MODULA 제품소개

HORIZONTAL CAROUSEL

Picking made simple and reliable

The new Modula Horizontal Carousel

Based on thirty years of experience in the American market, the new Modula horizontal carousel was developed, taking into consideration, up to date safety, ergonomics, efficiency and productivity standards.

It is ideal for all intensive picking applications, in both distribution and production environments, or in facilities where it is not possible to use vertical space due to height restrictions.

Each carousel is composed of a series of bins that rotate horizontally on a stainless steel track and bring the products ready for picking to the operator in the picking area, using to the goods-to-person concept.

The advantages of Carousels

PRODUCTIVITY INCREASES Following the “goods-to-person” concept, the products are brought directly to the operator, eliminating any waste of time compared to traditional manual picking methods.

MAXIMIZES THE USE OF SPACE Products are stored and organized in a compact and high density storage area.

REDUCES RISKS AND IMPROVES ERGONOMICS Operators work in safe and ergonomic conditions. The safety systems prevent all contact with the moving parts of the carousel.

FULL TRACEABILITY AND REAL-TIME INVENTORY All picking operations are monitored and documented, enabling full traceability of orders and stock levels.

FLEXIBILITY FOR EVERY STORAGE NEED The management of the carousel units, as well as the distance between the shelves for the bins, can be easily adjusted to adapt them to changing product mixes or to meet temporary needs like seasonal orders.

PRECISION PICKING Thanks to visual aid systems, operators can quickly identify which and how many products to pick. This reduces human error, increasing pick accuracy to over 99%.

QUICK RETURN ON INVESTMENT The ROI ranges between 6 and 18 months, depending on the size nd characteristics of the design.

TRACK MADE OF STAINLESS STEEL

SHELVES PITCH 5 mm

LOAD-BEARING CAPACITY 36 T MAXIMUM

SPEED OF ROTATION 26 m / min

TRACK MADE OF STAINLESS STEEL

SHELVES PITCH 5 mm

LOAD-BEARING CAPACITY 36 T MAXIMUM

SPEED OF ROTATION 26 m / min

| Model | Bin width (mm) | Bin height (mm) | Bin depth (mm) | Carousel height (mm) | Inverted motor carousel height (mm) | Bin capacity (kg) | Shelf load capacity (kg) |

|---|---|---|---|---|---|---|---|

| MD84 | 610 | 2,134 | 457 | 3,023 | 2,743 | 550 | 110 |

| MD84D | 610 | 2,134 | 610 | 3,023 | 2,743 | 550 | 110 |

| MD96 | 610 | 2,438 | 457 | 3,327 | 3,048 | 550 | 110 |

| MD96D | 610 | 2,438 | 610 | 3,327 | 3,048 | 550 | 110 |

| MG84 | 914 | 2,134 | 457 | 3,023 | 2,743 | 550 | 110 |

| MG84D | 914 | 2,134 | 610 | 3,023 | 2,743 | 550 | 110 |

| MG96 | 914 | 2,438 | 457 | 3,327 | 3,048 | 550 | 110 |

| MG96D | 914 | 2,438 | 610 | 3,327 | 3,048 | 550 | 110 |

Safe and flexible

Maximum attention to safety

Horizontal carousels were designed to guarantee the highest safety standards for both the operators and for the goods stored in them.

Each unit is supplied with:

- automatic door

- 2.4 m high perimeter fence with safety door and key switch for the entire unit.

Automatic doors

The high-speed automatic doors (opening/closing) guarantee operator safety as they prevent access to moving parts until the carousel is completely still and ready for picking. The doors are made of high-strength polycarbonate and were specially designed with a semi-curved and highly ergonomic design to facilitate picking operations for operators. The doors are also equipped with sensors to prevent foreign objects from accidentally interfering with the closing of the doors, the force of which is also calibrated to prevent crushing injuries.

Carousel units

In order to increase productivity, horizontal carousels can be used in groups, also known as “pods”. Different configurations are available, consisting of 2, 3 or 4 carousels.

2 CAROUSEL

3 CAROUSEL

4 CAROUSEL

While the operator picks from one carousel in a pod, the other carousels rotate and prepare the material for the subsequent picks. This minimizes operator downtime, exponentially increasing performance. Each picking station can allow up to 500 picks/hour.

Excellent adaptability

Horizontal carousels can be installed in environments with particular geometrical structures or in sites with architectural obstacles.

For this reason they were designed to ensure maximum installation flexibility.

- The distance between carousels can be adjusted to circumvent obstacles, such as support columns etc.

- The control panel can be positioned at different points of the installation, according to the specific requirements.

- The perimeter fence is normally designed to suit the specific installation site.

Ease of use

Everything under control with a simple graphic interface

The horizontal carousel uses the control systems and graphic interfaces of all other Modula products. This makes it extremely familiar and intuitive to use, for those who already use Modula vertical storage systems as well as for new users. In particular, the following are supplied:

- A main control panel, used for assembly and maintenance of the carousels. An emergency stop button and a key switch for maintenance are available on the panel. Only one control panel is supplied for each pod.

- The operator interface consists of a tablet, positioned on the side of the door of each carousel. Each carousel is therefore equipped with a dedicated tablet. Each station is also equipped with an end picking button and an emergency stop button.

Precision picking with visual aids

The tablet placed next to the door has a graphic display which shows the compartment from which the item(s) should be picked, as well as the description and quantity of the items involved in the operation. For faster and more precise picking and replenishing operations, each automatic door is also equipped with LED light bars. This visual aid immediately indicates to the operator on which shelf the bin the item is to be picked from is located.

Modula WMS software

Modula WMS is the ideal warehouse management software for Modula automatic vertical and horizontal systems. It enables the real-time management of the storage system as well as the management of user and item data, locations, material handling, picking and placing orders, inventories, integration with ERP systems, and more.

Even higher productivity with our picking solutions

- Put to light

-

Put to Light solutions are the best choice for order preparation when a fast, intuitive, scalable and error-free process is required.

In a Put to Light system, the displays visually guide the operator to the locations in which the items for each order must be put. A luminous display is associated with each location or bin assigned to an order. Sorting is carried out by item. Once an item has been identified, the displays visually indicate to the operator the bin in which it must be placed and the quantity required for each order. The Modula WMS software that manages the Put to Light system allows the implementation of different picking strategies, including batch picking or multi-order.

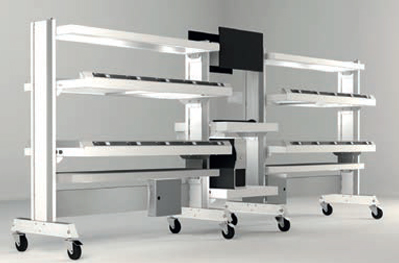

- Picking station

- A picking station is fixed, complete and modular, equipped with various picking positions. It is made of a sturdy painted steel structure, shelves to support the bins and a number of Put to Light displays with relative controller / power supply. The modules can be coupled to allow the expansion of the station for those who need to process many orders simultaneously. Intermediate modules are also available for the installation of monitors, label printers, barcode readers or other accessories. The system must be equipped with the Modula WMS software.

- Picking cart

-

A picking cart is a mobile, complete and modular station, equipped with various picking positions.

It consists of a painted steel trolley equipped with 4 pivoting wheels for easy maneuverability, shelves for bins, a certain number of Put to Light displays with relative controller, power / backup batteries and WiFi system for wireless connectivity. The system must be equipped with the Modula WMS software.

Accessories